Best quality Mini Beer Brewing Equipment - Malt Milling in Micro Brewery – Alston Detail:

Description

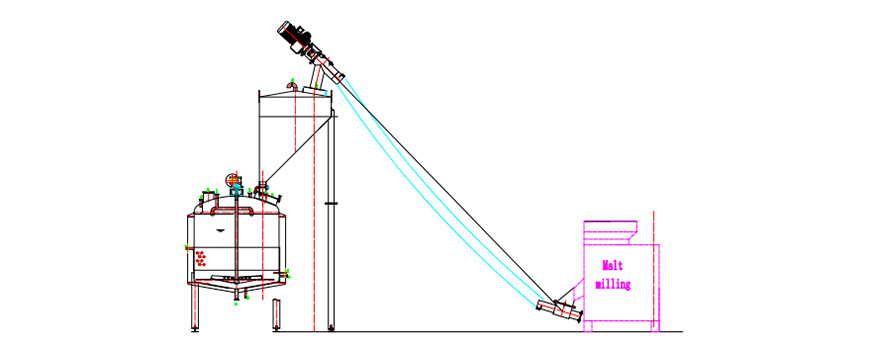

Main equipment of the malt processing system:

Malt grain mill machines – Machines for fine squeezing of malt grains to make the endosperm accessible without damaging the outer parts of grain which serves like the wort filtering material.

Screw conveyors – Machines for the transport of malt from the warehouse to the hopper of the malt crusher, then to the brewhouse and for the transport rests of waste malt grains from the brewhouse to the storage waste containers.

Malt scales – Meters for accurate weighing of malt before its squeezing.

Hoppers and silos for the malt storage and other machinery and equipment for convenient malt storage and malt handling.

According to your brewery size, then we can provide you 100kg/h-3000kg/h. Also with flex auger, malt silo and accessories.

In addition, according to your automatic level, we can equip you weight model for counting the weight of malt and recipe.

So, pls contact us for getting more information.

The details as below: (500kg/h as sample)

1. Crushing Ability:300-500kg/h

2. Power:1.5KW

3. Shell: carbon steel or stainless steel

4. Double rollers,material: Alloy

5. Rollers gap adjustable; Maxroller speed: 700RPM

6. Ratio of magnetic metal material: ≤0.003G/KG

7. Temperature of rollers afterrunning: ≤56°C

9. New type double rollers malt miller, equipped with motor, belt pulley, belt, hopper, etc

10. Automatically remove the iron and dust, Low noise

Product detail pictures:

Related Product Guide:

We offer fantastic energy in high quality and enhancement,merchandising,profits and promoting and procedure for Best quality Mini Beer Brewing Equipment - Malt Milling in Micro Brewery – Alston, The product will supply to all over the world, such as: Casablanca, Egypt, Frankfurt, We confirm to public, cooperation, win-win situation as our principle, adhere to the philosophy of make a living by quality, keep developing by honesty , sincerely hope to build up a good relationship with more and more customers and friends, to achieve a win-win situation and common prosperity.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.

-

Hot New Products Beer Making Equipment - Comme...

-

New Arrival China Commercial Beer Brewing Equip...

-

Hot New Products Beer Making Equipment - Grape...

-

Factory Supply Used Beer Canning Equipment - C...

-

Free sample for Ss Brew Tank - Grape processin...

-

Hot sale Large Beer Brewery Equipment - Fully ...