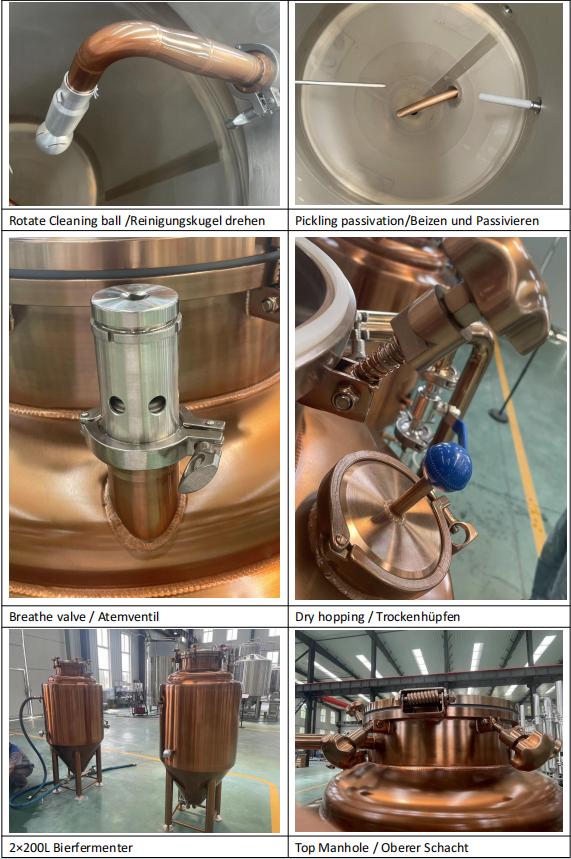

3HL Fermenter 2 pcs

•Material: AISI 304, Titanium -plated.

•Total volume: 4HL, effective volume:3HL, 25% head space, without domed head space

•Tank working pressure: 2bar, testing pressure: 3bar

•Jacket working pressure: 1bar, testing pressure: 2bar

•Inner tank thickness: 3mm, outer cladding: 2mm

•Polyurethane insulation, thickness: 80mm, side and bottom insulated

•Dimple plate cooling jacket

•Cooling stage: cylinder and cone, both jackets connected

•One temp control stage, PT100 Temp sensor

•Exterior: stain removed, and brightened on regular margin

•Interior surface: Polished, and welding joint acid cleaned

•Roughness: 0.4um

•Domed top, 60 degree cone angle

•4 pcs stainless steel leg, with adjustable leg bolt

•Top fittings: CIP arm, spray ball, PVRV, dry hopping port

•Side fittings: Glycol inlet/outlet, thermo well, sample port, side manway

•Bottom fittings: Drain outlet, beer outlet

•CIP arm including diaphragm pressure gauge

•Mechanical pressure valve mounted with CIP arm

•Dry hopping port on top

•Racking arm

•Carbonation unit with tanks

Fittings quantity:

•4* butterfly valves (bottom drain,beer outlet, 2 for CIP arm, )

•1* breathe valve on tank top

•1*bunging device installed with CIP arm

•1*CIP arm

•1* pressure indicator

•1* temp sensor

Post time: Jul-24-2023