Factory source Brewing - 10HL, 20HL,30HL 3 Vessel Brewing System – Alston Detail:

Description

The traditional three vessel brewhouse configuration is mash tun + lauter tun + kettle / whirlpool combined, or mash / boiling tank + lauter tun + whirlpool tank.

That’s still available with mash lauter tank+brew kettle+whirlpool for meet brewing process.

Brewhouse is designed and fabricated as the exact brewing process request from client and the local requirement. Tanks size designed as exact beer plato / gravity from client.

The goal is helping client with easy brewing operation, making the whole brewhouse setup more suitable for right recipe , increasing the efficiency and lowering the energy cost etc

The whole system is Luxurious looks, has to be the best choice for the craft brewery.

Also we designed a hop filter, wort buffer tank, Simply pipelines designed and equipped with SUS 304 plate heat exchanger; the whole system can be separately controlled by a panel.

The biggest advantage is continue to brewing and brew 4-6 batch per times for continue brewing, more in line with the brewing process.

Capacity: 10HL 20HL 30HL 40HL Or 10BBL 15BBL 20BBL 30BBL or customized

Heating method: steam (recommended)

Efficiency: 4- 6 Brews per day

Standard setup

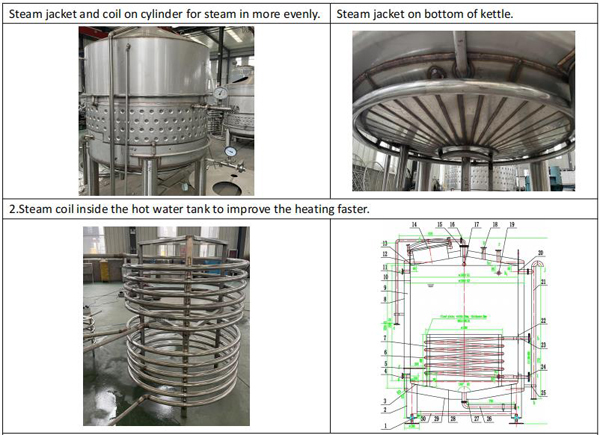

● Mash tun with bottom paddle type stir, bottom & steam jacket, separate control

● Lauter tun with bottom stir blade, counter washing and wort collect coil

● Kettle / whirlpool combined, with side and steam jacket, separate steam control for different batch size.

● Support fittings: double / single stage plate cooler, piping strainer, grist hydrator, wort sink etc

● Layout: All in line or tri angle

● Standard brewhouse platform or customized

● All pump & Stir with VFD

● With hot water tank configured for sparging and mashing in etc.

● Valves to be manual butterfly one or pneumatic

● Piping connection to be TC or DIN.

● Separate HLT to be configured for continuous brewing

Features

● Higher wort wort extract

● Lower energy cost and material consumption

● Well adjusted temp and water blending unit for better grain and water mixing

● Higher efficiency steam jacket to increase heating efficiency and lower energy consumption

● Special tank and piping construction to avoid the wort aeration problem and decrease the material lost

● Special designed steam condensing unit, with both steam condensing and water heating function

● Brewhouse automation with possible upgrading.

Product detail pictures:

Related Product Guide:

To consistently enhance the management method by virtue of the rule of "sincerely, fantastic religion and top quality are the base of business development", we extensively absorb the essence of associated goods internationally, and constantly acquire new merchandise to satisfy the needs of shoppers for Factory source Brewing - 10HL, 20HL,30HL 3 Vessel Brewing System – Alston, The product will supply to all over the world, such as: Pakistan, Roman, Pakistan, We have been fully aware of our customer's needs. We deliver high quality products, competitive prices and the first class service. We would like to establish good business relationships as well as friendship with you in the near future.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!