Free sample for Ss Brew Tank - Commercial Winery Equipment & Supplies – Alston Detail:

Description

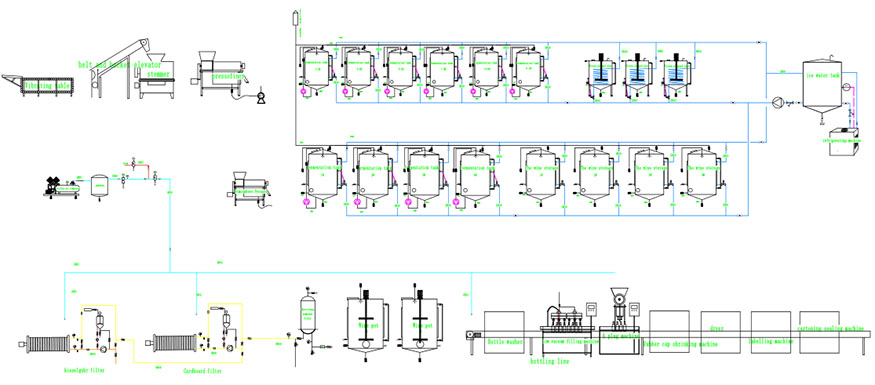

|

1 |

Pre-processing equipment |

Raw material vibration selection table Hoist Destemming crusher Screw press Movable bladder press (for wine pressing) |

|

2 |

Fermentation equipment |

Dry white wine fermentation tank Dry red wine fermentation tank Wine storage tank Freezing tank Finished tank |

|

3 |

Distillation equipment |

Distillation equipment Brandy distillation unit |

|

4 |

Cooling unit |

Refrigeration unit Glycol liquid tank |

|

5 |

Filtering system |

Diatomite filter Cardboard filter Membrane filtration equipment Thin plate heat exchanger Peel pump (screw type pomace pump) |

|

6 |

Filling system |

Automatic bottle washing machine Filling machine Stopper Dryer Heat shrinkable rubber cap machine Labeling Machine Tape sealing machine |

|

7 |

Cleaning system |

CIP unit |

|

8 |

Control system |

PLC controller for control the temperature of tanks |

Alston company can design customized wine and fruit wine fermentation system equipment according user’s requirements, including wine storage tank, freezing tank, floating roof tank, refrigerant tank, heat medium tank, cold medium pipelines, platform, refrigeration unit, control system, CIP cleaning system, etc. It can meet the requirements of different production process, such as red wine, white wine, sparking wine and ice wine.

In order to meet the needs of customers, our company can provide you with fully automic or semi-automci production lines according to users requirements.

1. Pre-treatment system: Grape destemming crusher, screw pump,membrane press, grape vibration separator, scrapter elevator, belt vonveyor.

2. Fermentation system: accoridng to the user’s requirements, several wine femneters can be cnfigured to realize enzymatic hydrolysis, clarication, cold impregnation, hot imprenation, alcohol fermentation, apple-milk fermentation, freezing and other process, and the temperature is automaticlly controlled during the fermentation process.

3. Filtration system: Diatomite filter, cardboard filter, membrane filter.

4. Package system: Gravity filling machine, plugging machine, rubber cap shrinking machine, labeling machine and so on.

5. Auxilliary system: CIP unit, sterilization machine, mobile pump, refrigeration unit, control system and others.

Wine fermenters

1. Wine fermenters are widely used in the fermentation of red wine, white wine, rose wine, and sparkling wine.

2. Fermenter configuration cooling, heating jacket, according to different process requirements, can achieve enzymatic hydrolysis, clarification, cold impregnation, hot impregnation, alcohol fermentation, pin-milk fermentation process automatic temperature control to users.

3. All the products of the company are designed with the customer’s process requirements as the center, whcih can meet the requirments of the company to the maximum extent.

Product detail pictures:

Related Product Guide:

We always continually provide you with the most conscientious customer service, and the widest variety of designs and styles with finest materials. These efforts include the availability of customized designs with speed and dispatch for Free sample for Ss Brew Tank - Commercial Winery Equipment & Supplies – Alston, The product will supply to all over the world, such as: Borussia Dortmund, Malta, Johannesburg, Our expert engineering team will generally be prepared to serve you for consultation and feedback. We are able to also offer you with free of charge samples to meet your requirements. Best efforts will likely be produced to provide you the best service and merchandise. When you are keen on our business and products, please speak to us by sending us emails or call us quickly. In an effort to know our products and company extra, you may come to our factory to view it. We will generally welcome guests from all over the world to our business to create business relations with us. Please feel cost-free to speak to us for small business and we believe we'll share the best trading experience with all our merchants.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.