High Quality for Copper Beer Equipment - Brewery Manual control system – Alston Detail:

Advantages

● Reduction in labor

● Improved beer quality and consistency

● Automatic brewhouse temperature, material flow, and temperature control of your cellar tanks (fermentation tank, brite beer tank, etc)

● Energy Recovery

● System configuration for a link to Internet

● Automatic access to production and equipment communication

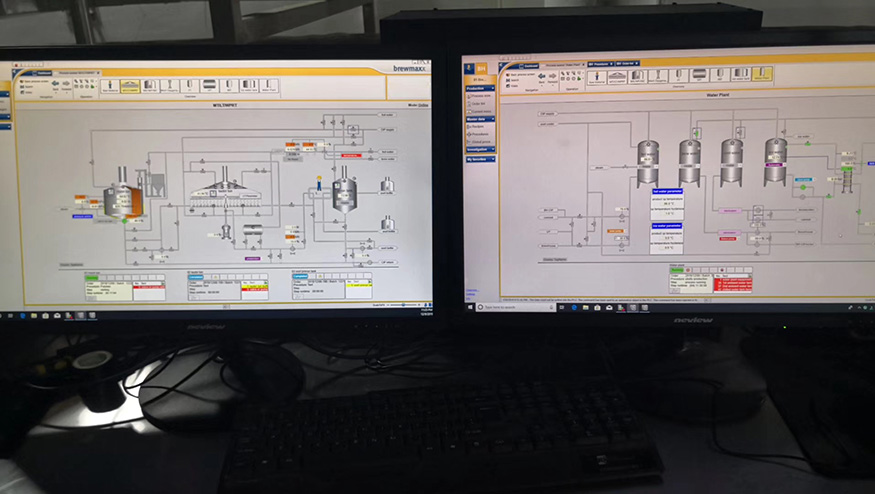

Our programming team has streamlined automatic control systems for efficiency and easy operation. Over the last ten years, we have built up an excellent relationship with the Rockwell & Siemens systems operation division.

Also we can offer CE, UL, and CUL certified control cabinets with electronic elements suitable for customers all over the world.

With this automated control system, you can monitor working conditions on your smart device as long as you have access to internet.

Monitor

● Pressure

● Temperature

● Cellar tanks – glycol tank, fermenters, brite beer tanks, etc.

Function

Brewhouse control:

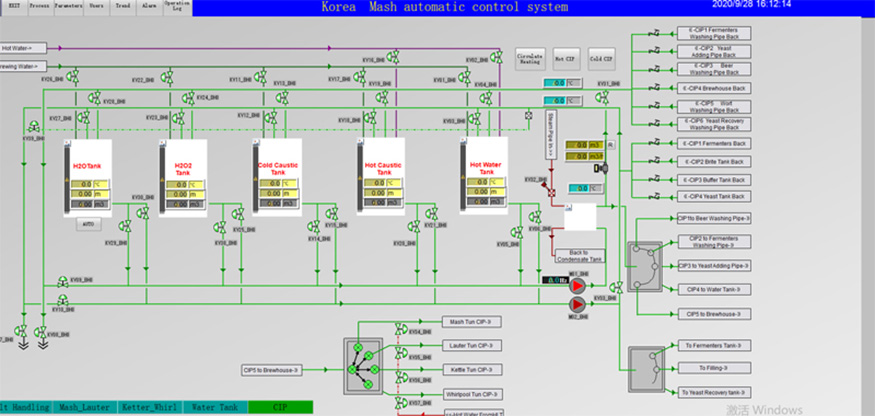

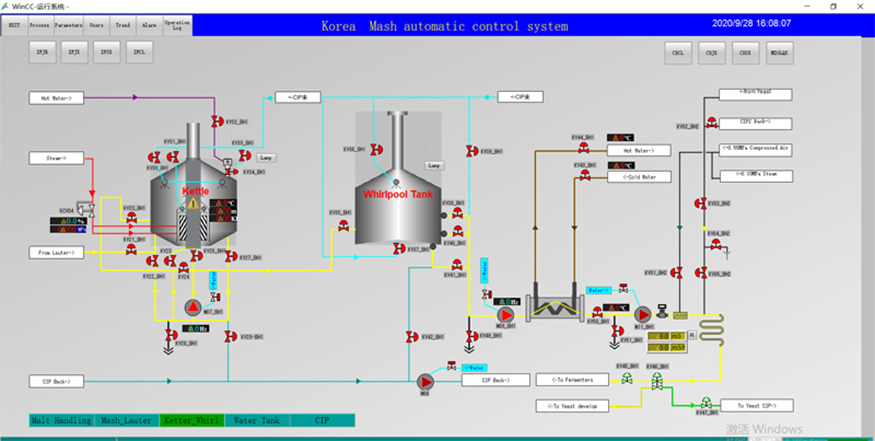

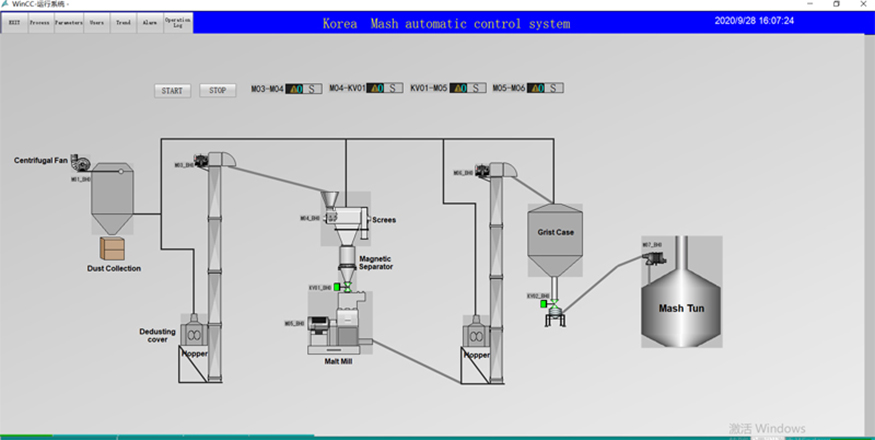

The saccharification control system is pneumatic valve control (using industrial control machine for control).

1. The temperature of the mashing pot is fully automatic.

2. The turbidity of wort in the filter tank is detected by a turbidity meter.

3. The steam heating of the boiling pot is controlled by a thin-film steam regulating valve, and the valve opening can be adjusted to control the amount of steam.

4. Saccharification pots and filter tanks are equipped with liquid level switches, and boiling pots, rotary sinks, cold water and hot water tanks are all equipped with electronic level gauges.

Fermenter’s control:

● Ice water tank and cold water tank temperature display.

● Control fermentation tank temperature.

● Control glycol pump frequency converter and motor.

● Control cooling system temperature.

● Temperature is controlled by solenoid valve.

● Temperature self-control.

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our firm for the long-term to create jointly with consumers for mutual reciprocity and mutual reward for High Quality for Copper Beer Equipment - Brewery Manual control system – Alston, The product will supply to all over the world, such as: St. Petersburg, Jeddah, Albania, Look forward to the future, we will focus more on the brand building and promotion . And in the process of our brand global strategic layout we welcome more and more partners join us, work together with us based on mutual benefit. Let's develop market by fully utilizing our comprehensive advantages and strive for building.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.

-

Hot-selling Beer Brewing Equipment Micro Brewer...

-

China wholesale Water Tank - Stainless steel w...

-

Best quality Mini Beer Brewing Equipment - 10H...

-

Manufactur standard Beer Plant - Grape process...

-

2022 Good Quality Microbrewery Equipment For Sa...

-

Good Quality Beer Equipment - 4 Vessel Commerc...