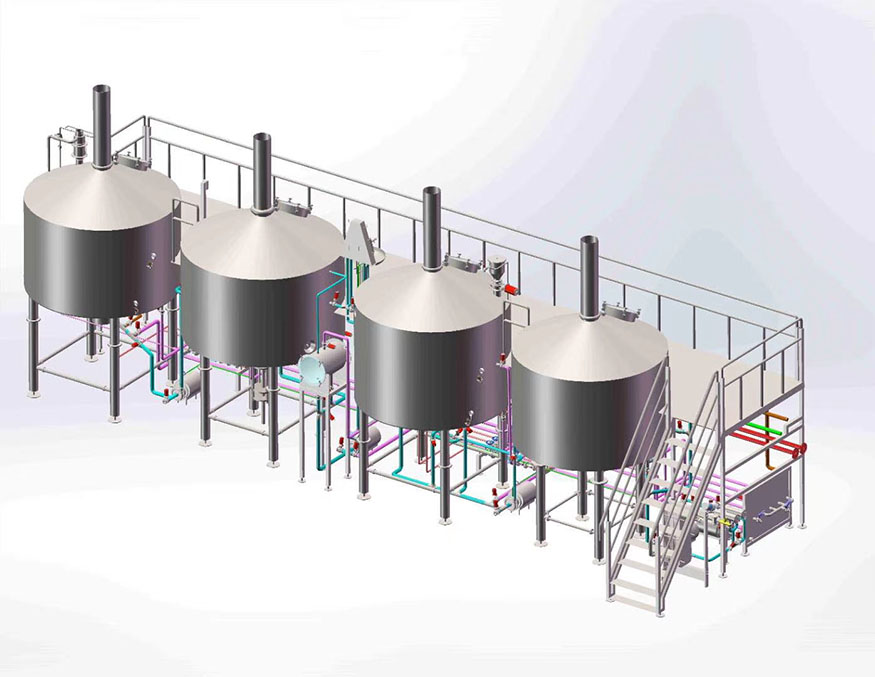

Manufactur standard Beer Plant - 5000L Commercial Brewery Turnkey Project – Alston Detail:

Features

1. Safety

● All tank fabrication procedures follow a strict quality control program.

● Control panel lockout switches for brewer safety standard item on systems..

● Brewhouse vessel orientation designed to prevent boil over danger to brewer.

● Overflow tube on all hot and cold liquor tanks.

2. Flexibility

● Design and customize equipment to meet individual customer’s site and capacity requirements.

● Range of brewing options including half or double batches, high gravity beers, infusion, temperature profile and decoction brewing.

● Kettle heating options including electric, direct fire or steam, depending on site and local utility costs.

● Top or side manways (with hop dosing port) on cellar tanks.

3. Easy to installation and use

● Fast installation due to precision pre-fitted piping at factory and quick on-site reassembly time.

● Adjustable legs on vessels for ease of levelling and final placement.

● The systems are designed by brewers and engineers providing a simple design that’s easy to use, safe and highly efficient.

● Simple and easy-to-operate brewing pipeline, clamp or round thread connection, no dead corners, convenient and practical;

4. Durablity

● High-quality selection of accessores equipment for improved long-term system performance and low maintenance costs.

● Industry-leading 5 year warranty on all fabricated vessels for long-term hassle-free operation.

● Stainless steel work platform for integrity, no rusting and long life.

● Tanks are tested prior to shipment to avoid on-site repairs, guarantee uninterrupted startup and assured vessel performance.

Specifications

| Brewhouse Capacity | 2000-5000Litre/brew |

| Materials | SUS 304 or 316 Stainless Steel |

| Interior Finish | Acid washing and passivation or mirror polishing |

| Polishing Precision | 0.2~0.4μm |

Standard Configurations

1.Malt milling system:

Malt milling machine

Flex auger

2.Combined 4-Vessels Brewhouse System, 2000L-5000L:

* Mash Tun

* Lauter Tun

* Brew Kettle

* Whirlpool Tun

* Cooking tank for corn

* Hot Liquor Tank

* Cold Liquor Tank for optional.

* Support customization.

3. Glycol Jacketed Conical Fermentation Tank:

Fermentation Tank, according to beer type and brewing area, then you can choose 4sets, 6 sets, 8sets or more.

*Support customization.

4.Cooling Unit:

* Glycol Water Tank

* Chiller

* Centrifugal Pump

5.Controlling Unit:

Brewery Instrumental Control Cabinet

Or PLC control system

6.Cleaning Unit:

CIP Unit

7.Filling unit for optional.

*All the items listed above could be custom made upon your particular needs.

For more details, please feel free to contact us by email or by the inquiry sheet.

Product detail pictures:

Related Product Guide:

abide by the contract", conforms on the market requirement, joins within the market competition by its superior quality likewise as provides far more comprehensive and great company for shoppers to let them develop into huge winner. The pursue on the corporation, is definitely the clients' gratification for Manufactur standard Beer Plant - 5000L Commercial Brewery Turnkey Project – Alston, The product will supply to all over the world, such as: Ghana, San Francisco, Georgia, Furthermore, all of our items are manufactured with advanced equipment and strict QC procedures in order to ensure high quality. If you are interested in any of our goods, please don't hesitate to contact us. We will do our best to meet your needs.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.

-

Manufactur standard Beer Plant - 20HL 30HL 40H...

-

Factory wholesale Brewery Equipment Beer Brewin...

-

High reputation Beer Dispenser Equipment - Bee...

-

Factory Supply Used Beer Canning Equipment - F...

-

Best quality Mini Beer Brewing Equipment - Bre...

-

New Arrival China Commercial Beer Brewing Equip...