Wholesale Beer Manufacturing Equipment - Malt Milling in Micro Brewery – Alston Detail:

Description

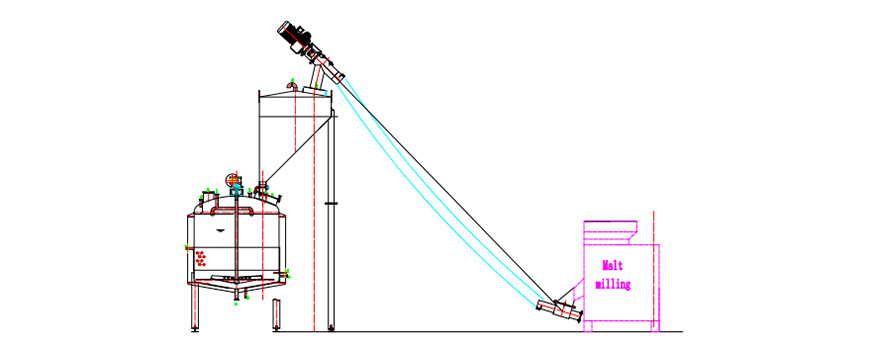

Main equipment of the malt processing system:

Malt grain mill machines – Machines for fine squeezing of malt grains to make the endosperm accessible without damaging the outer parts of grain which serves like the wort filtering material.

Screw conveyors – Machines for the transport of malt from the warehouse to the hopper of the malt crusher, then to the brewhouse and for the transport rests of waste malt grains from the brewhouse to the storage waste containers.

Malt scales – Meters for accurate weighing of malt before its squeezing.

Hoppers and silos for the malt storage and other machinery and equipment for convenient malt storage and malt handling.

According to your brewery size, then we can provide you 100kg/h-3000kg/h. Also with flex auger, malt silo and accessories.

In addition, according to your automatic level, we can equip you weight model for counting the weight of malt and recipe.

So, pls contact us for getting more information.

The details as below: (500kg/h as sample)

1. Crushing Ability:300-500kg/h

2. Power:1.5KW

3. Shell: carbon steel or stainless steel

4. Double rollers,material: Alloy

5. Rollers gap adjustable; Maxroller speed: 700RPM

6. Ratio of magnetic metal material: ≤0.003G/KG

7. Temperature of rollers afterrunning: ≤56°C

9. New type double rollers malt miller, equipped with motor, belt pulley, belt, hopper, etc

10. Automatically remove the iron and dust, Low noise

Product detail pictures:

Related Product Guide:

Our mission will be to become an innovative supplier of high-tech digital and communication devices by furnishing benefit added structure, world-class manufacturing, and service capabilities for Wholesale Beer Manufacturing Equipment - Malt Milling in Micro Brewery – Alston, The product will supply to all over the world, such as: Argentina, Cyprus, British, We solution have passed through the national skilled certification and been well received in our key industry. Our specialist engineering team will often be ready to serve you for consultation and feedback. We are able to also provide you with no cost samples to meet your needs. Best efforts will be produced to offer you the very best service and solutions. For anyone who is considering our business and solutions, please speak to us by sending us emails or get in touch with us right away. As a way to know our products and enterprise. lot more, you'll be able to come to our factory to find out it. We will constantly welcome guests from around the globe to our firm. o build enterprise. elations with us. Please really feel absolutely free to make contact with us for small business and we believe we will share the top trading practical experience with all our merchants.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.

-

High Quality for Copper Beer Equipment - Draft...

-

Low price for Beer Pasteurization Equipment - ...

-

2022 Good Quality Microbrewery Equipment For Sa...

-

Manufactur standard Beer Plant - Horizontal B...

-

Chinese Professional Bright Beer Tank - Stainl...

-

Hot-selling Beer Brewing Equipment Micro Brewer...