High Quality for Copper Beer Equipment - 5BBL,7BBL,10BBL Traditional 2vessel Brewhouse – Alston Detail:

Description

Capacity: 5HL, 10HL, 15HL, 20HL Or 5BBL 7BBL 10BBL 15BBL or customized

Material: SUS304, 316L (inside),

Heating method: Electric / steam / gas fired

Efficiency: 1-3 Brews per day

The traditional two vessel brewhouse configuration is mash tun / lauter tun + kettle / whirlpool combined,

which is more used for brewers from North America for infusion brewing.

The brewhouse following exact building requirement and the exact beer gravity from different investors.

Piping works for the brewhouse is easier but more professional to make sure there is less wasting and everything following customers brewing recipe requirement.

Standard setup

● Mash / lauter tun with top or bottom blade stir, counter washing and wort collect coil

● Kettle / whirlpool with tangent inlet, electric heater inside tank, steam jacket or gas chamber underneath.

● Support fittings: double / single stage plate cooler, piping strainer, grist hydrator, wort sink etc

● Standard brewhouse platform or customized

● All pump & Stir with VFD

● With hot water tank configured for sparging and mashing in etc.

● Valves to be manual butterfly one or pneumatic

● Piping connection to be TC or DIN.

● Hot water tank to be 2-3 times bigger for mashing, sparging and cleaning

Features

Features:

● Reasonable water blending unit for temp and water amount control

● Well sized tank diameter to guarantee right filtration are for wort extract

● Lower energy cost and material consumption

● Wort grant creating more buffer during lautering

● Wort dam in kettle for clearance wort

● Special tank and piping construction to avoid the wort aeration problem and decrease the material lost

● Whole brewhouse unit can be installed on frame

Options

● Optional copper cladding

● Customers logo can be engraved

● Mash / lauter tun with steam jacket for decoction brew.

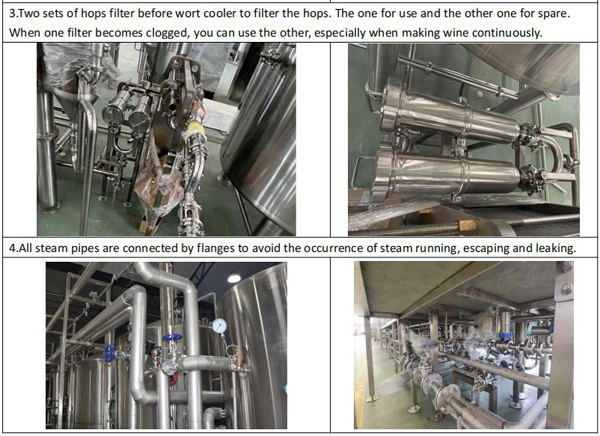

Product detail pictures:

Related Product Guide:

With a positive and progressive attitude to customer's interest, our company continuously improves our product quality to meet the needs of customers and further focuses on safety, reliability, environmental requirements, and innovation of High Quality for Copper Beer Equipment - 5BBL,7BBL,10BBL Traditional 2vessel Brewhouse – Alston, The product will supply to all over the world, such as: Congo, moldova, Indonesia, The development of our company not only needs the guarantee of quality, reasonable price and perfect service, but also relies on our customer's trust and support! In the future, we are going to continue with the most qualified and high quality service to offer the most competitive price, Together with our customers and achieve win-win! Welcome to inquiry and consult!

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.

-

Professional China Commercial Beer Brewery Equi...

-

Professional China Commercial Beer Brewery Equi...

-

Top Suppliers Beer Maker - Semi-Automatic Brew...

-

Good quality Brewery Equipment Beer Brewery Equ...

-

Cheap price Beer Brewing Equipment 30l - Beer ...

-

Good Quality Beer Equipment - 4 Vessel Commerc...